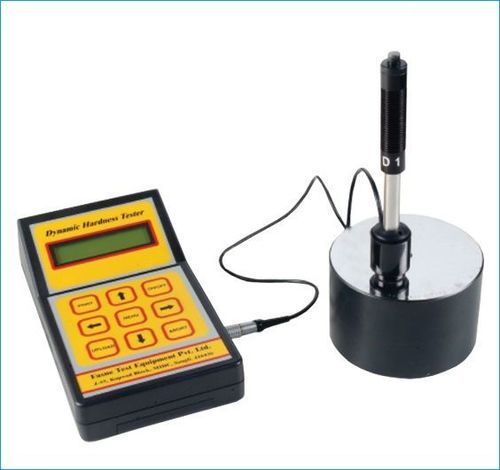

Portable Hardness Tester-I

Product Details:

- Dimension (L*W*H) 152X76X33

- Power Supply 1.5 VDC X 2Nos.

- Machine Weight 0.3 Kilograms (kg)

Portable Hardness Tester-I Price And Quantity

- 1 Number

- 1 INR/Number

Portable Hardness Tester-I Product Specifications

- 152X76X33

- 1.5 VDC X 2Nos.

- 0.3 Kilograms (kg)

Portable Hardness Tester-I Trade Information

- Cheque Telegraphic Transfer (T/T)

- 1 Number Per Day

- 1 Week

- All India

Product Description

Application

Permanently assembled and installed parts.

large and heavy components in forging, tool room, foundries & Heat Treatment units.

measurement of hardness in confined spaces.

Material identification of metallic material.

surface hardened components.

Features

Large LCD Display(128X64 dot matrix) showing hardness value, Direction of impact device, hardness scale, material, test Time for average and battary icon

Direct Display of hardness in HV, HB, HRC, HRB, HRA and HS Scales.

7 types of impact devices can be attached for special application and need not to be recalibrated when changing them.

the machine identify the type of impact device automatically

Upto 600 groups (impact times:32 1) of data can be stored in internal memory of the machine.

Upper and lower limit of hardness can be preset. when the tested value exceeds the limits, alarm buzz automatically

Back light on/off facility is given by pressing key to make machine converient for use in poor light.

User Calibration function.

By Using Software, data can be transfered and saved in pc for future use.

Different types of impact devices and there uses

Impact Device D :Universal Standard Impact device use for testing majority of metallic components

Impact device DL:Testing of slender, narrow groove and extermely confirmed spaces.

Impact Device DC:Extremely short impact device for very confirmed space such as holes, cylinders etc.

Impact Device DL+15 :Slim front section with coil set back used in grooves, recessed surface like T-Slot

Impact Device C :Low impact energy device used for testing case hardened, coating and thin walledcomponents.

Impact Device G :Suitable on heavy components such as rough casting and forgings in brinell scale only.

Impact Device E :Suitable for testing super high hardness material.

Other Products in 'Portable Hardness Tester ' category

|

OM ENGINEERING INSTRUMENTS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese